Quaterways Multidirectional Shuttle

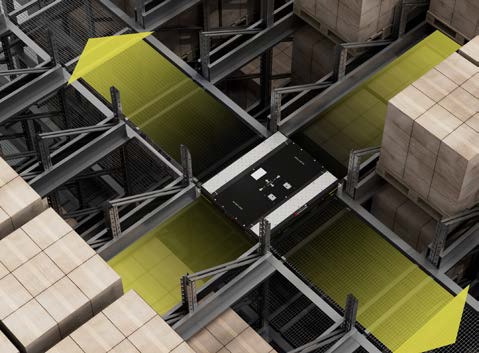

Maximum efficiency and high-density pallet storage for complex warehouse layouts

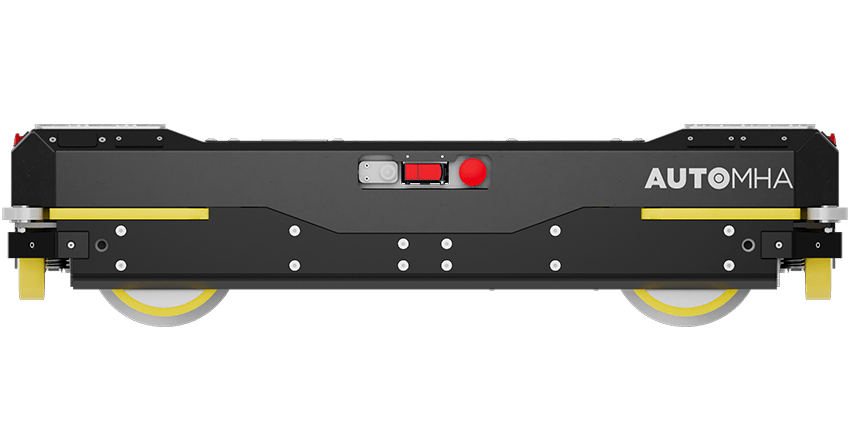

The Quaterways multidirectional shuttle is an advanced pallet shuttle system designed for automated pallet handling in multi-level racking. Developed by Automha and distributed in New Zealand by PHS Innovate, it delivers a highly adaptable warehouse shuttle system that moves independently in all directions, optimising space, boosting throughput, and enabling true warehouse automation.

Unlike traditional pallet shuttle racking systems, Quaterways can navigate complex layouts with ease, offering the flexibility needed for both new facilities and retrofits in high-turnover or high-density storage systems.

How it works:

The Quaterways multidirectional shuttle is designed to deliver fast, precise, and fully automated pallet handling within multi-level racking. In operation, the pallet shuttle system collects a pallet from the front of the racking, with the Automha Warehouse Management System (AWMS) determining the optimal storage position and calculating the most efficient route.

Using its integrated elevator, the warehouse shuttle system moves to the correct racking level before travelling along the aisle to the designated storage position. Guided by advanced sensors and real-time cameras, the shuttle lifts the pallet slightly and places it in the deepest available location, maximising high-density pallet storage.

Once the pallet is in position, the shuttle exits the aisle and reintegrates into the warehouse flow, ready to begin the next task as part of your wider warehouse automation strategy.

Key features

- Multidirectional movement: Travels along both axes for maximum flexibility.

- Modular and scalable: Expand capacity by adding more shuttles as needed.

- High versatility: Accommodates different pallet formats and SKUs in the same channel.

- Advanced control: AWMS software manages movements in real time for precision and efficiency.

- No busbars required: Wi-Fi communication reduces infrastructure impact.

- Energy efficient: Ideal for cold storage automation, reducing costs and operator exposure to low temperatures.

- 48V lithium-ion battery: Safe, reliable power supply for long shifts.

- Brushless motors: Durable, low-maintenance drive system

Benefits

- Maximise warehouse capacity: Achieve high-density pallet storage without expanding your footprint.

- Increase productivity: Reduce handling times and accelerate throughput.

- Adapt to complex layouts: Configure the pallet shuttle automation to fit your existing racking and space constraints.

- Reduce operating costs: Lower energy consumption, labour requirements, and maintenance downtime.

- Enhance safety: Minimise manual handling and operator exposure in cold or high-traffic areas.

- Future-proof your operation: Easily upgrade and expand as your business grows

Applications

- High-turnover warehouses: Streamline large volumes of inbound and outbound pallets.

- Intensive storage: Maximise space in operations with many pallets per SKU.

- Refrigerated and frozen storage: Optimise cold store layouts while cutting energy use in automated warehouse storage environments.

Transform your warehouse operations with the Quaterways multidirectional shuttle. Contact us today to discuss how we can design a customised automated storage and retrieval system solution that boosts efficiency, reduces costs, and positions your business for future growth.