When it comes to warehousing and inventory management, understanding the value of every square metre in your facility is crucial. PHS Innovate is at the forefront of revolutionising storage solutions across Australia, New Zealand and the Pacific, urging businesses to move beyond traditional selective racking systems that by nature come with constraints.

Our partnership with AutoMHA introduces high-density storage solutions that not only optimise space but significantly enhance operational efficiencies, positioning them as the superior choice for forward-thinking businesses.

What is High-Density Storage?

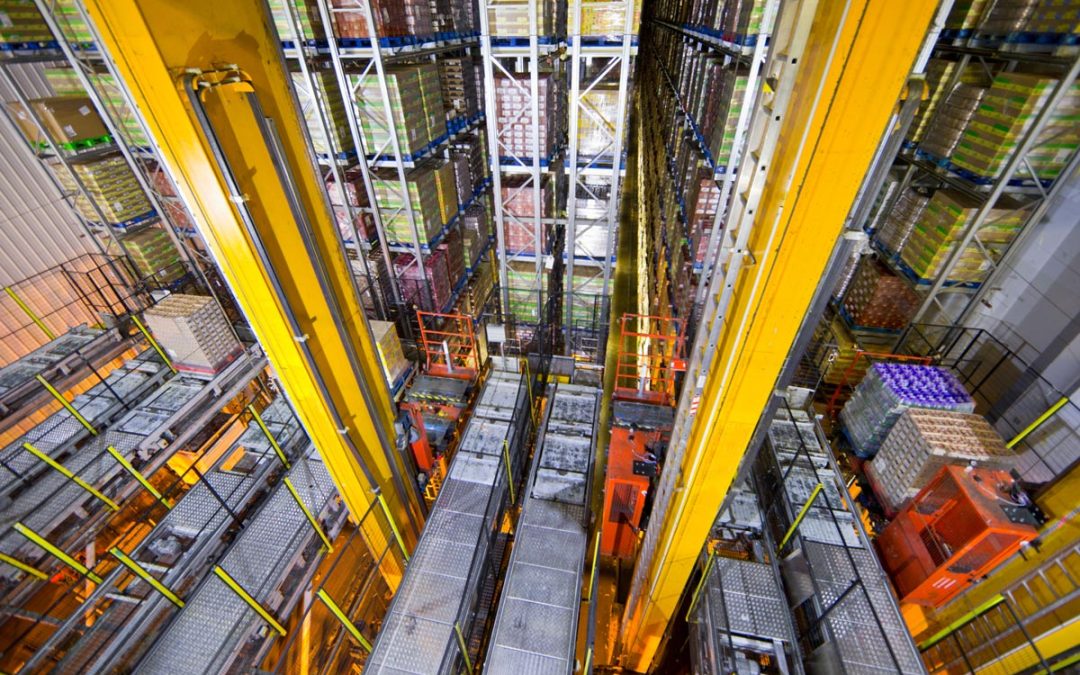

High-density storage systems maximise warehouse space by significantly reducing aisle width and increasing usable height. These systems are equipped with sophisticated automated technologies, like those from AutoMHA, which streamline operations by enabling efficient storage and retrieval processes. Such configurations can support both Last In, First Out (LIFO) and First In, First Out (FIFO) inventory management, crucial for different product types and turnover rates.

Pitfalls of Continuing to Use Forklifts

In traditional racking systems such as selective, very narrow aisle (VNA), or double-deep, forklifts are used to move pallets to the rack. Drive-in systems require operators to enter the rack structure to store and retrieve pallets, heightening risks of structural damage, compromising safety, and jeopardising pallet integrity. This necessity poses significant risks, particularly when navigating with pallets suspended at high levels—a situation fraught with potential accidents and inefficiencies.

Why Automated Systems Are Superior

Automated systems eliminate the need for operators to enter rack structures, thus improving safety, reducing potential damage, and maintaining the integrity of stored goods. Automation ensures precise handling and placement of goods, minimises damage and loss, and enhances inventory accuracy, significantly improving supply chain reliability. Furthermore, automation facilitates faster retrieval times, leading to higher throughput and better customer service.

That’s why the Australian Government have developed The National Robotics Strategy to responsibly grow Australia’s robotics and automation ecosystem.

Space Efficiency

High-density storage solutions can transform a limited warehouse footprint into a highly efficient storage facility. By minimising aisle space and leveraging vertical storage, these systems can increase storage capacity by as much as 60% compared to regular selective racking. This capability is pivotal for businesses that face spatial constraints and wish to increase their storage density without the costs associated with physical expansion.

Cost-Effectiveness

The economic advantages of high-density storage are many. Reduced physical footprint lowers heating, cooling, and lighting expenses. Furthermore, the automation inherent in these systems minimises labour costs and enhances inventory accuracy, which in turn reduces waste and improves order fulfilment accuracy.

Scalability and Flexibility

One of the standout features of high-density storage solutions is their scalability. Systems designed by AutoMHA can be adapted and reconfigured to accommodate varying inventory sizes and types, providing businesses with the flexibility to respond to market demands without additional capital investment in new storage facilities.

“The automated system is pretty simple so training staff is very easy. Once you have a basic understanding of how the system works it’s very user-friendly. The team at PHS Innovate are always friendly and always helpful. I’ve got a lot of their personal numbers so if we ever need anything they’re always available and most of the time answer straight away.”

Andre De Beer

Dispatch and Automation Coordinator

Talley’s Limited

Conclusion

In today’s rapidly evolving market, standing still is not an option. Adopting high-density storage solutions is not merely about enhancing efficiency—it’s about future-proofing your business. The transition to automated systems, as provided by PHS Innovate and AutoMHA, represents a critical step towards modernising operations and ensuring that your business is not left behind in an increasingly competitive landscape. By choosing to innovate now, you secure a scalable, flexible, and safer future for your operations, positioning your company as a leader rather than a follower.

About PHS Innovate. From our engineering base in New Zealand, PHS Innovate offer customised materials handling products and systems across Australia, New Zealand, and the Pacific region. Whether you’re a multinational company with complex production lines or a smaller business looking to scale up, we build solutions that fit your specific needs. Contact us today to discuss your project.