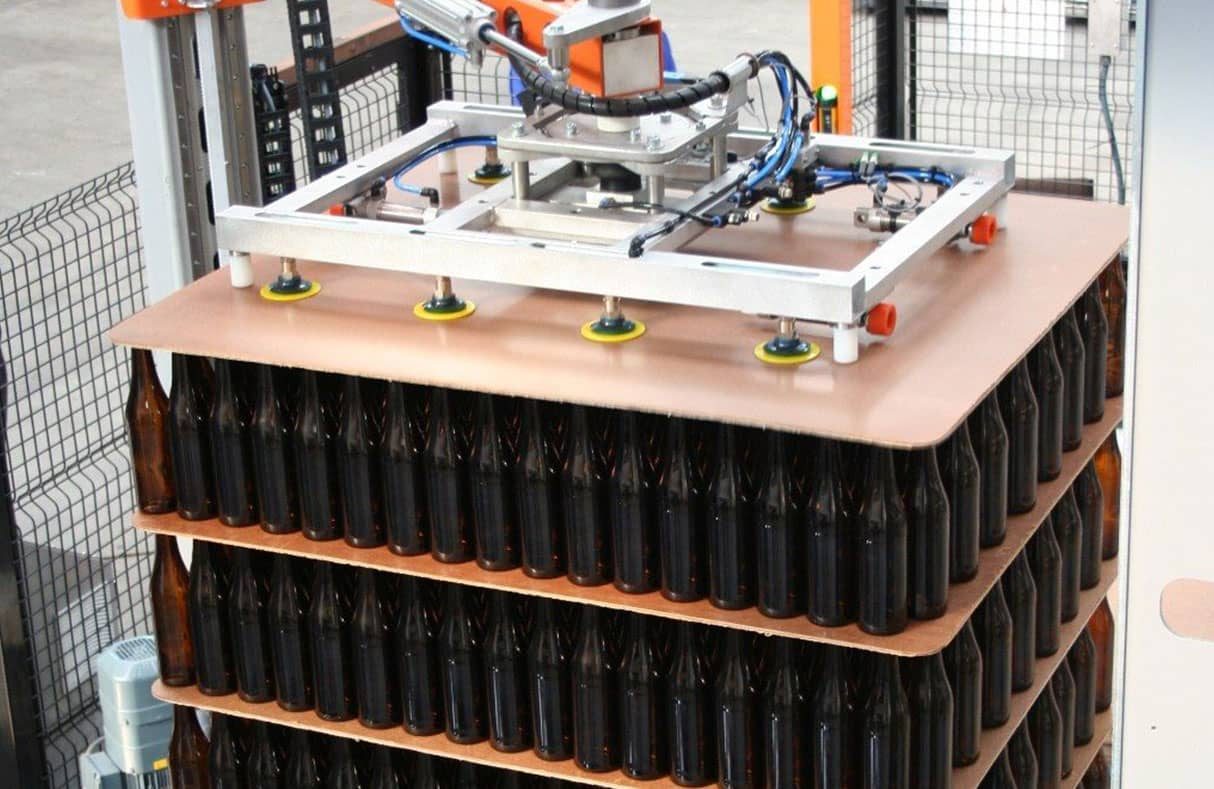

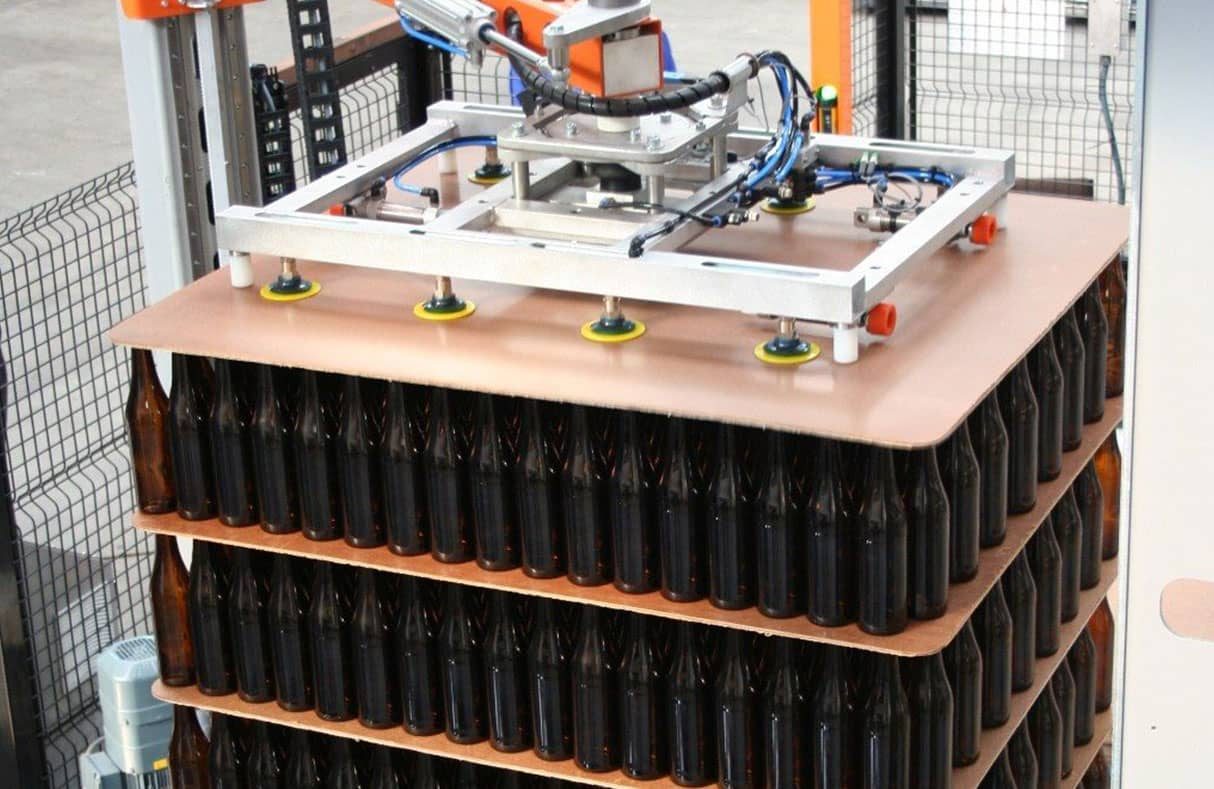

Automatic Depalletizer

Elevate your material handling automation with the PHS300 Automatic Depalletizer, proudly serving industries across Australia and New Zealand.

The PHS300 Automatic Depalletizer is a fully integrated system designed to streamline your depalletizing operations. Capable of handling a wide array of containers – including glass bottles and jars, plastic (PET) bottles and containers, and aluminium cans. PHS300 depalletizer brings unparalleled flexibility to your production line. Serving businesses throughout Australia and New Zealand, we understand the unique needs of these markets and offer solutions tailored to meet them.

With its flexible, modular design, the PHS300 can be easily customised to fit your specific requirements. Whether you need to adapt to existing line configurations or accommodate future expansions, this depalletizer offers the adaptability you need for sustained operational excellence.

Ready to find your solution?

PHS Innovate Automated Depalletizer Features:

- Standard Product Discharge: Compatible with most production lines.

- Optional Elevated Discharge: Adapts to existing line configurations.

- Operator and Machine Interface at Ground Level: Enhances safety and ease of use.

- Simple Product Change-Over: Minimises downtime during transitions.

- Pallet Stack Height Detection: Adjusts to varying pallet heights.

- 4-Sided Clamping: Ensures secure handling of products.

- Stack Stabilising Mechanism: Prevents toppling during operation.

Tier Sheet Gripping: Allows precise transfers. - Removal of Tier Sheets and Empty Pallets: Streamlines operations.

- Optional End or Side Discharge and Single Filer: Offers versatility in configuration.

- Multiple Configurations Available: Customisable to suit your industry.

PHS Innovate Automated Depalletizer Features:

- Standard Product Discharge: Compatible with most production lines.

- Optional Elevated Discharge: Adapts to existing line configurations.

- Operator and Machine Interface at Ground Level: Enhances safety and ease of use.

- Simple Product Change-Over: Minimises downtime during transitions.

- Pallet Stack Height Detection: Adjusts to varying pallet heights.

- 4-Sided Clamping: Ensures secure handling of products.

- Stack Stabilising Mechanism: Prevents toppling during operation.

Tier Sheet Gripping: Allows precise transfers. - Removal of Tier Sheets and Empty Pallets: Streamlines operations.

- Optional End or Side Discharge and Single Filer: Offers versatility in configuration.

- Multiple Configurations Available: Customisable to suit your industry.

Benefits of the PHS300

Implementing Automatic Depalletizing systems offers numerous advantages for your production line. Designed with flexibility in mind, the PHS depalletizers allow for simple and quick change-overs between different product types and sizes. This minimises downtime and maximises productivity, adapting swiftly to your production needs.

- Increased Efficiency: Automates critical steps, enhancing overall operational speed.

- Reduced Manual Labour: Minimises the need for manual intervention, lowering labour costs.

- Enhanced Safety: Reduces the risk of workplace injuries by minimising manual handling tasks.

- Flexible Integration: Easily customizable to fit into various production line setups.

- Scalability: Suitable for both small and large-scale operations, adapting to your growing needs.

Industry Applications, Customization, Integration & Maintenance

Our depalletizer is designed with a flexible, modular architecture that allows for easy customisation. Whether you require specific discharge options or integration with your existing discharge table and other factory automation systems, the PHS300 can be optimised to meet your unique production requirements. This adaptability ensures that the depalletizer seamlessly fits into your current workflow and can be utilised across multiple industries:

- Food and Beverage: Efficiently handles jars, cans and bottles, ensuring quick and safe case depalletizing.

- Pharmaceuticals: Maintains the integrity of sensitive products during this process.

- Consumer Goods: Streamlines packaging and warehouse and distribution operations, enhancing productivity.

Further our expert engineers are dedicated to ensuring your equipment operates smoothly, minimising downtime and maximising productivity. From initial installation to ongoing maintenance we are here to support your material handling automation.

Industry Applications, Customization, Integration & Maintenance

Our depalletizer is designed with a flexible, modular architecture that allows for easy customisation. Whether you require specific discharge options or integration with your existing discharge table and other factory automation systems, the PHS300 can be optimised to meet your unique production requirements. This adaptability ensures that the depalletizer seamlessly fits into your current workflow and can be utilised across multiple industries:

- Food and Beverage: Efficiently handles jars, cans and bottles, ensuring quick and safe case depalletizing.

- Pharmaceuticals: Maintains the integrity of sensitive products during this process.

- Consumer Goods: Streamlines packaging and warehouse and distribution operations, enhancing productivity.

Further our expert engineers are dedicated to ensuring your equipment operates smoothly, minimising downtime and maximising productivity. From initial installation to ongoing maintenance we are here to support your material handling automation.

Get Started with Our Depalletizing Automation Solution Today

Ready to enhance your production line with depalletizers? Contact the PHS Innovative team today for support with your next warehouse or factory automation project. Let us help you streamline your depalletizing process, improve efficiency, and achieve greater productivity.