Efficient and Reliable Palletizing Solutions Designed for Australia and New Zealand Businesses

If you are in the manufacturing, warehousing, or distribution business, palletizing is an integral part of your operations, enabling the efficient arranging and stacking of goods onto a pallet for storage, transportation, or shipping. Palletizers play a crucial role in streamlining the supply chain and ensuring timely delivery of products to customers.

Manual palletizing processes, often seen as monotonous and physically demanding, can lead to errors, damage to goods, and even worker injuries. This is especially true when dealing with heavy loads or awkwardly shaped products. As a business owner, you want to ensure your operations are efficient and your workers are safe. That’s where automated palletizers come in.

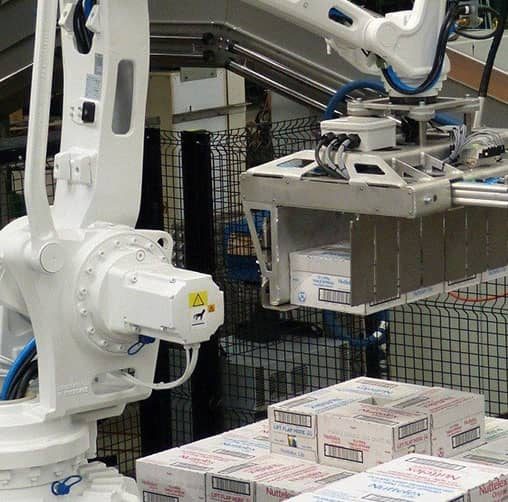

At PHS Innovate, we provide robotic palletizing solutions in New Zealand, Australia and the Pacific region. Our automated systems are designed to handle a variety of products, including bags, cases, crates, and more. Automating the palletizing process can save time and reduce labour costs while minimising errors and accidents.

Ready to find your solution?

Do you need to increase efficiency, reduce handling accidents and RSI repetitive strain injuries in your factory or warehouse? Is it getting harder to recruit workers for exhausting manual tasks like palletizing? Moving to an automated palletizing solution could be a game changer for your business.

Whether you are in food, beverage, pharmaceuticals, or any other industry, our palletizing systems, including integrated pallet wrapping machines, can easily handle a wide range of products. We are your go to specialists in Australia and New Zealand that offer end-to-end palletizing services, from concept to installation and maintenance.

At PHS Innovate, we offer a range of palletizing solutions, including traditional layer building, and robotic machines. These machines are suitable for palletizing bags, cases, trays, or crates.

What Our Palletizers Can Handle

At PHS Innovate, our state-of-the-art automated and robotic palletizers are engineered to handle a diverse array of products across various industries. Our versatile palletizing solutions ensure reliability, efficiency, and performance tailored to your specific operational needs. Here’s a look at what our palletizers can handle:

Bags: Versatility in Handling Various Bag Types

Our palletizers are adept at managing different types of bags, ensuring smooth and efficient stacking without compromising the integrity of your products.

- Material Handling: Whether you’re dealing with paper bags, plastic bags, woven polypropylene bags, or multi-layer composite bags, our palletizers can handle them with ease.

- Sizes and Weights: From lightweight flour bags to heavy-duty industrial sacks, our systems accommodate a wide range of sizes and weights, ensuring flexibility in your operations.

- Speclialised Configurations: Our palletizers can manage bags with unique features such as gusseted sides, zipper closures, or reinforced handles, maintaining their integrity during the palletizing process.

Crates: Precision and Strength for Any Application

Our crate palletizers are designed to efficiently handle various crate types, ensuring stability and strength in every pallet configuration.

- Variety of Crates: From the food and beverage industry to pharmaceuticals and electronics, our systems can manage different materials and designs of crates depending on the industry application.

- Customisable Stacking Patterns: Whether you need low level palletizer or you looking for multi-level stacking configurations, our palletizers can be designed and programmed to meet required stacking requirements.

- Heavy Loads: Capable of handling heavy loads, our palletizers ensure safe and secure stacking.

Cases and Boxes: Efficient Management of Standard Packaging

Our palletizing solutions excel in handling cases and boxes of various sizes and materials, enhancing your packaging workflow.

- Shorter Cycle Times: Our advanced robotic bag palletizer is engineered for exceptional speed, cutting cycle times by up to 25% of the industry benchmark. This significant reduction in cycle times enhances throughput and dramatically boosts productivity.

- Maximise Your Production Space: Our robotic palletizer features a compact design that easily integrates into your existing setup, allowing you to make the most of your production area for enhanced efficiency and output.

- Protect Your Sensitive Products: Our robotic palletizer, equipped with advanced motion software, ensures smooth and precise handling, significantly reducing the risk of damage to your sensitive products for greater product integrity and customer satisfaction.

- Reduced Maintenance Costs: The robot’s robust design and integrated process cabling reduce wear and extend the equipment’s lifespan, leading to lower maintenance requirements.

What Are the Key Differences Between a Conventional Layer Style Palletizer and Robotic Palletizer?

Choosing the right palletizing system requires understanding the fundamental differences between conventional layer palletizers and robotic palletizers.

Conventional Layer Palletizers

Speed and Efficiency

- High Throughput: Conventional automated palletizers are designed for high-speed operations, making them ideal for industries that require rapid palletizing of uniform products (Handles 1 SKU at a time).

- Mechanical Simplicity: They utilise mechanical components and straightforward movements, which can result in reliable performance and easier maintenance.

Limitations

- Less Flexibility: These systems are typically optimised for specific product sizes and configurations. Adjusting to different product types may require mechanical changes.

- Space Requirements: Conventional palletizers often have a larger footprint due to their mechanical nature and may require more floor space in your facility.

Robotic Palletizers

Flexibility and Adaptability

- Versatile Handling: Robotic palletizers use articulated arms and can handle a variety of products, sizes, and pallet patterns without extensive reconfiguration (Handles multiple SKUs at a time).

- Easy Programming: Adjustments for new products or patterns can often be made through software updates, reducing downtime and increasing adaptability.

Advantages

- Space Efficiency: With a more compact design, robotic palletizers are suitable for facilities with limited space.

- Future-Proofing: Their adaptability makes them a scalable solution that can evolve with your business needs.